This article mainly analyzes the historical development of the European UV LED curing market as well as subsequent technological breakthroughs and market prosperity.

With the increase in continuous advancement of R&D technology, UV LED technology is gradually emerging in the European market. Over the years, the European UV LED market has experienced significant growth and technological breakthroughs, leading to a prosperous market.

Doubts and Hesitation

Since the introduction of the first arc lamp over 70 years ago, followed by microwaved-powered lamps for generating UV light, doubts have persisted regarding the long-term viability of UV technologies. Consequently, printers have been hesitant to fully embrace UV due to a lack of confidence. Effective curing has required a collaborative approach, involving the integration of printing presses, UV lamp units, and ink formulations. However, concerns about quality, cost, and odors have often overshadowed these efforts.

Discover the potential of LED

The launch of UV LED units in the early 2000s surprisingly did not face much skepticism regarding its potential for curing. Unlike mercury-based equipment, LED systems utilize solid-state semiconductor light-emitting diodes to convert electrical current into UV radiation.

In terms of performance, UV LED initially fell short compared to conventional mercury-based UV processes, as it only covered a limited UV spectrum range of 355-415 nanometers and emitted primarily low power suitable for spot curing.

However, optimists recognized the promising aspects of UV LED, including its affordability, environmental friendliness, immediate start-up capability, and compatibility with temperature-sensitive and thin substrates. Furthermore, LED lights could be divided into separate zones using digital controls to target specific areas of the substrate with UV light.

Above all, UV LED represented an electronics-based process that promised greater opportunities for innovation compared to traditional UV systems. Its potential as a mercury lamp alternative was further emphasized by the upcoming phase-out of mercury under the 2013 international Minamata Convention.

The Expanding Applications

The maturity of technology has led to the widespread implementation of UV LED equipment, which can be used in sterilization, water treatment, surface decontamination and cleaning. Its expanded spectral range, power and energy provide deeper curing capabilities compared to traditional UV.

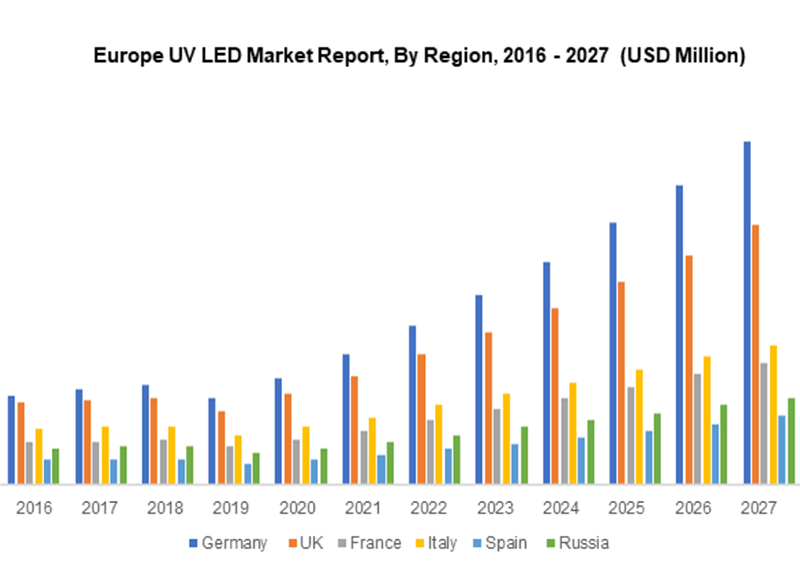

The growing UV LED market has attracted investment from international electronics manufacturers. Market researchers predict that the industry will experience double-digit growth rates globally, reaching a multi-billion dollar value by the mid-2020s.

As a trusted partner in the industry, UVET provides comprehensive support and technical expertise to its European clients, assisting them in optimizing their curing processes and achieving greater operational efficiency. Their dedication to customer satisfaction has earned them a strong reputation in the market.

Post time: Dec-04-2023